Our Products

DisplayMan boasts a wealth of expertise in delivering a captivating array of displays, from sleek monochrome LCDs to cutting-edge TFT LCDs, smart LCD and OLED displays, and even the interactive allure of TFT LCD Touch Screen Displays. Our offerings also include the brilliance of customized LED segment displays. Elevate your visual experience with DisplayMan’s versatile display solutions.

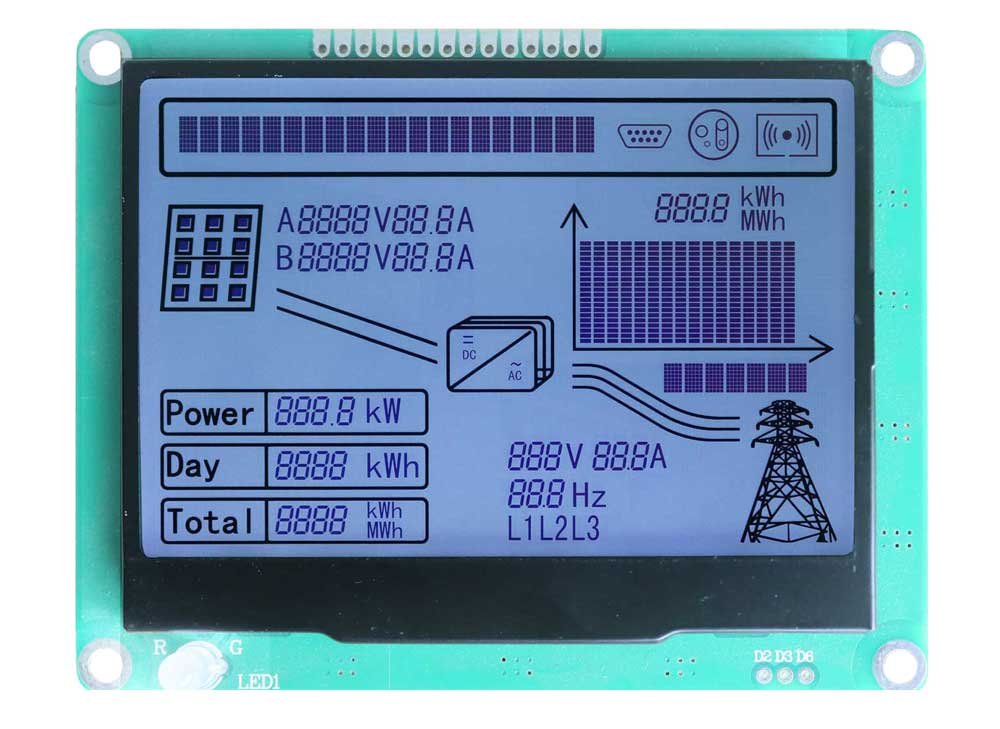

Monochrome LCD Displays

Unlock affordable excellence with our range of passive monochrome LCD display technologies. Explore character, graphic, COB, and COG LCD modules that redefine cost-efficiency.

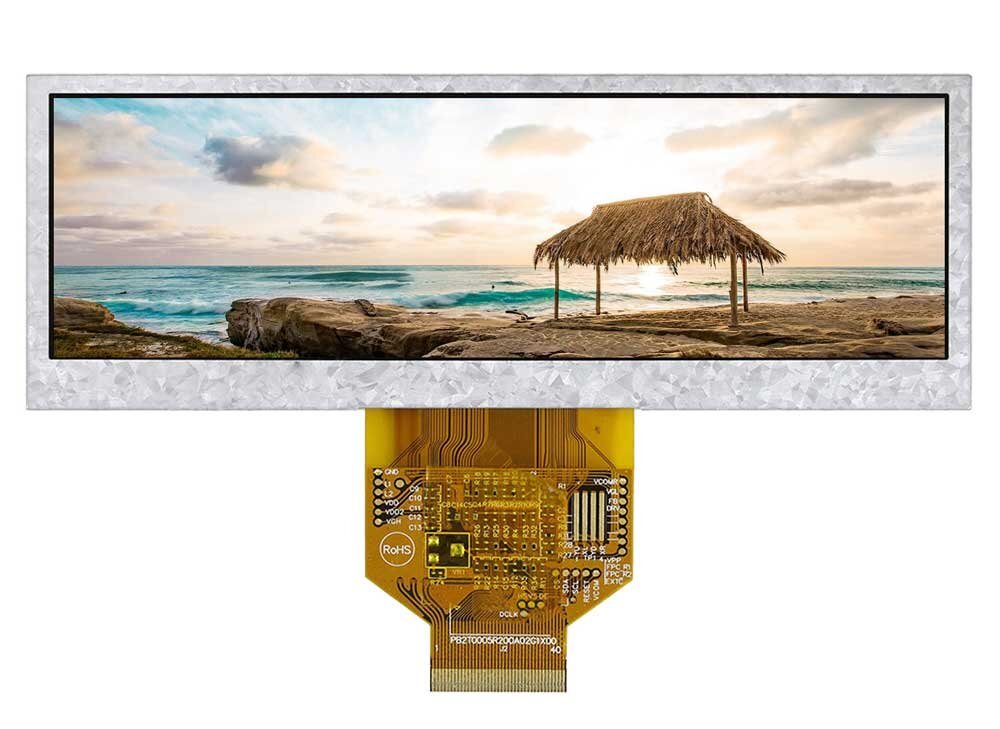

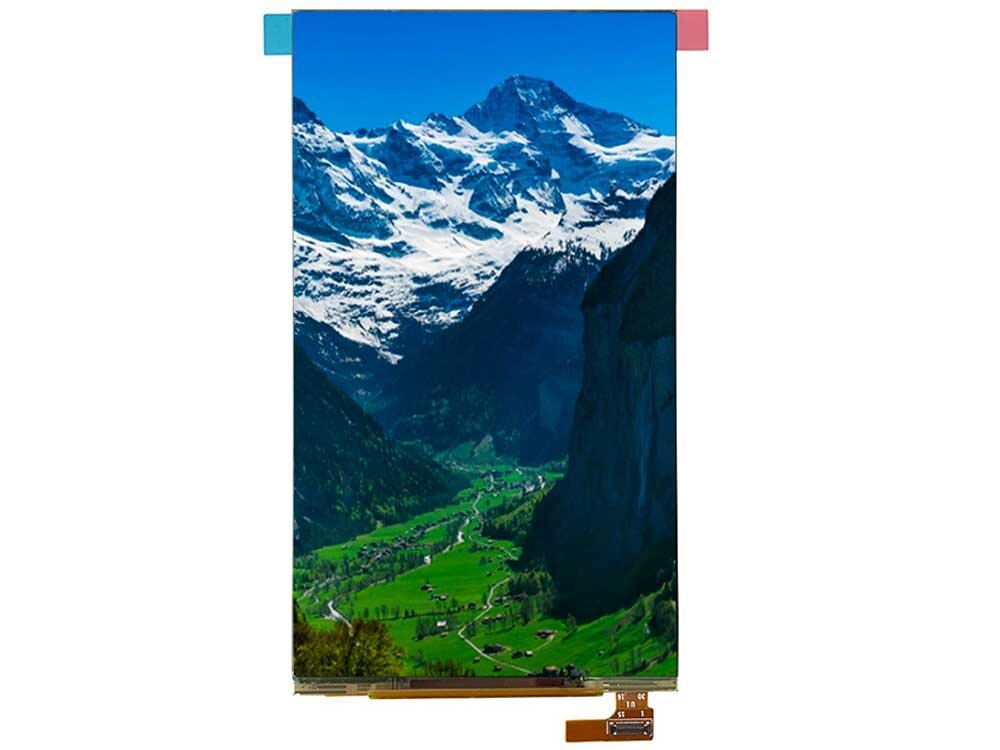

TFT LCD Displays

Discover brilliance with Color TFT LCD Displays up to 98.0" diagonally. Experience high-res visuals, dazzling brightness, and daylight readability with our custom solutions.

Smart LCD Displays

DisplayMan's Smart LCD Displays simplify product development by integrating key components, reducing time-to-market, and cutting costs. Join the display innovation with DisplayMan.

OLED Displays

Step into the future of displays with DisplayMan's cutting-edge ultra-thin AMOLED & PMOLED modules. Explore a world of vibrant visuals in sizes up to 5.5 inches diagonally – Embrace Innovation, Explore Possibilities, and Upgrade Your Display Today!

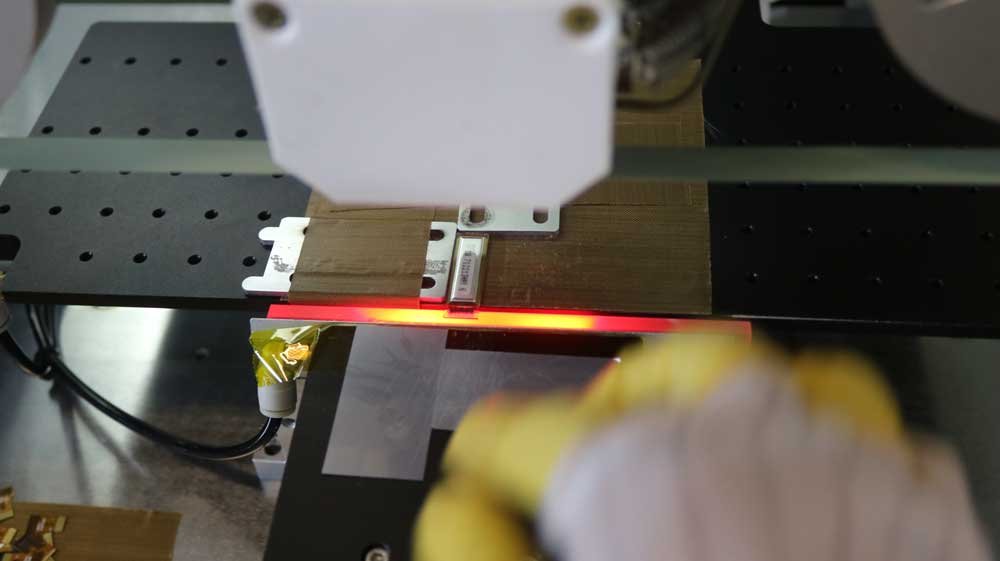

LED Backlights

Elevate your display with DisplayMan's high-quality LED backlight solutions. Illuminate your world with brilliance – Shine Brighter, Choose DisplayMan, and Transform Your Visual Experience Now!

LED Segment Displays

Elevate your display experience with DisplayMan's LED segment displays—crafted for ultimate customization, cost-efficiency, energy savings, durability, and longevity.

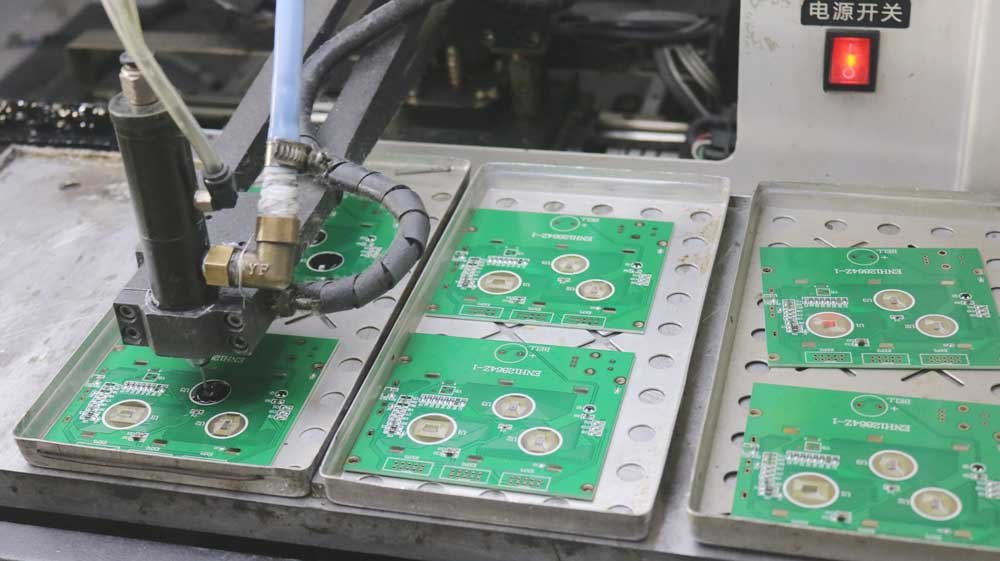

LCD Control Boards

Experience the ultimate control with DisplayMan's LCD Control Boards. Elevate your display performance today – Unleash, Customize, and Succeed!

TFT LCD Touch Screen Displays

DisplayMan excels in TFT LCD displays with touch panels, offering diverse sizes, resolutions, and customization options. We're your go-to resource for TFT LCD display solutions.

Touch Solution

Discover the future of interaction with TouchScreenMan's cutting-edge touch screen solutions. Elevate your experience – Touch, Explore, and Transform today!