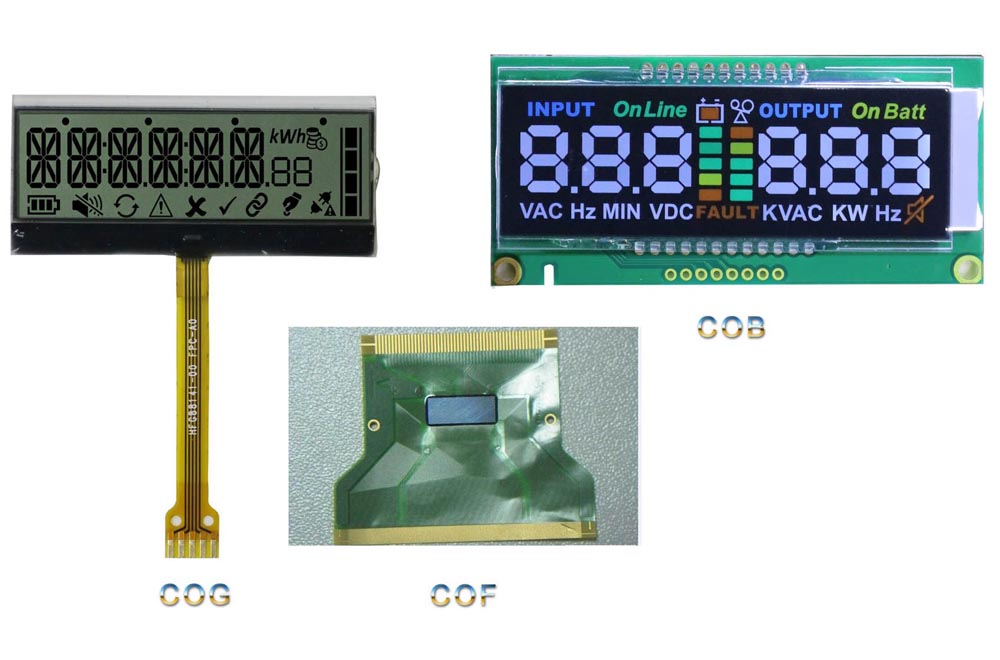

LCD Module(LCM) has 4 parts: LCD screen, LED backlight, IC and PCB (maybe a plastic shell). We can simply consider that it has two parts: LCD screen and LED backlight because we can see from the appearance that they are the main constituents. It can be divided into COB(chip on board), COG(chip on glass) and COF(chip on film) based on the position of chip. It can also be divided into graphic LCD module and character LCD module according to the resolution and character count.

1. COB LCD Module

COB is the abbreviation for “Chip On Board”, which is the most common way of processing the drive circuit board of LCM. The IC is attached directly to a specific location on the PCB with a sticky piece of plastic. See the picture below and the IC is under the black plastic. The electrodes of the chip are connected to the corresponding pads of the PCB board with aluminum wire by a soldering machine. And they are covered by a sticky piece of plastic on the surface.

COB LCD module is the most reliable technology which requires high precision equipment and a complicated processing procedure. It uses PIN or conductive rubber strip to connect and fasten the LCD screen, LED backlight and PCB all together, so it can’t be disconnected. It is very reliable and it can’t be damaged under normal circumstances. But if it is damaged, unfortunately, it can’t be repaired. It is an obsolete technology since it is too big and it is being replaced by COG LCD module.

2. COG LCD Module

COG is the abbreviation for “Chip On Glass”, where IC is bound to the ITO glass directly. Please see the picture below. It can greatly reduce the size of the LCD module and is easy for mass production of consumer electronic products, such as: mobile phone, PDA and other portable products.

COG LCD module doesn’t need a PCB. It is cheaper, isn’t it? I am sorry to tell you that it is not true. Actually, COG needs a dedicated glass mold and a dedicated mold of LCD FPC which COB doesn’t need. Maybe it needs a dedicated mold of light guide plate and a dedicated mold of backlight FPC because of its special structure. Thus, the tooling fee of COG is the most expensive among the three of them. If the quantity you want is only 1,000 pieces, the unit price will be incredibly high because of the tooling fee. At the same time, the tooling fee can be almost negligible if the order quantity is very large, say like 100 thousand, 1 million.

Is it reliable? Of course, it is very reliable. COB is the most reliable one. The reasons I think why COG is popular are that it can save a lot of space by concentrating all the functions on a single IC and it is cost-saving when the quantity is large. It is extremely important for modern portable electronic products which require a small volume.

3. COF LCD Module

COF is the abbreviation for “Chip On Film”, where IC is bound to a flexible film conveyor belt directly. Please see the picture below. It can greatly reduce the size of the LCD module, too.

We can barely see COF LCD module since no one makes it, I think it is best that we just follow the industrial tradition. It is really expensive if you want to make some special. Thus, if you really want to save space, I strongly suggest you choosing COG instead of COF.