LED light source is the best for all the light sources of backlight. The thickness of LED backlight is based on two important factors: the client requirements and the design requirements. Moreover, almost all the clients I have seen choose edge LED backlight. Why? The reason is very simple: it is very thin (1.00~5.00mm) and low power consumption, and the cost of production is only 1/2-1/3 as the bottom LED backlight. But there are some disadvantages for edge LED backlight that it is poor light uniformity and only good for small size. The large size edge LED backlight has a very poor light uniformity, and only the bottom LED backlight can meet the requirement of uniformity of large size light.

1. Bottom LED Backlight

The bottom LED backlight that LEDs are at the bottom of PCB and light directly irradiates on the surface of light guide plate is widely used by large-size liquid crystal display (LCD) modules, such as 32 inches and above. The advantage of bottom LED backlight is high illumination and high light uniformity. The structure of bottom LED backlight is more complicated than the structure of edge LED backlight. Usually, it requires a dedicated PCB and a dedicated plastic mold.

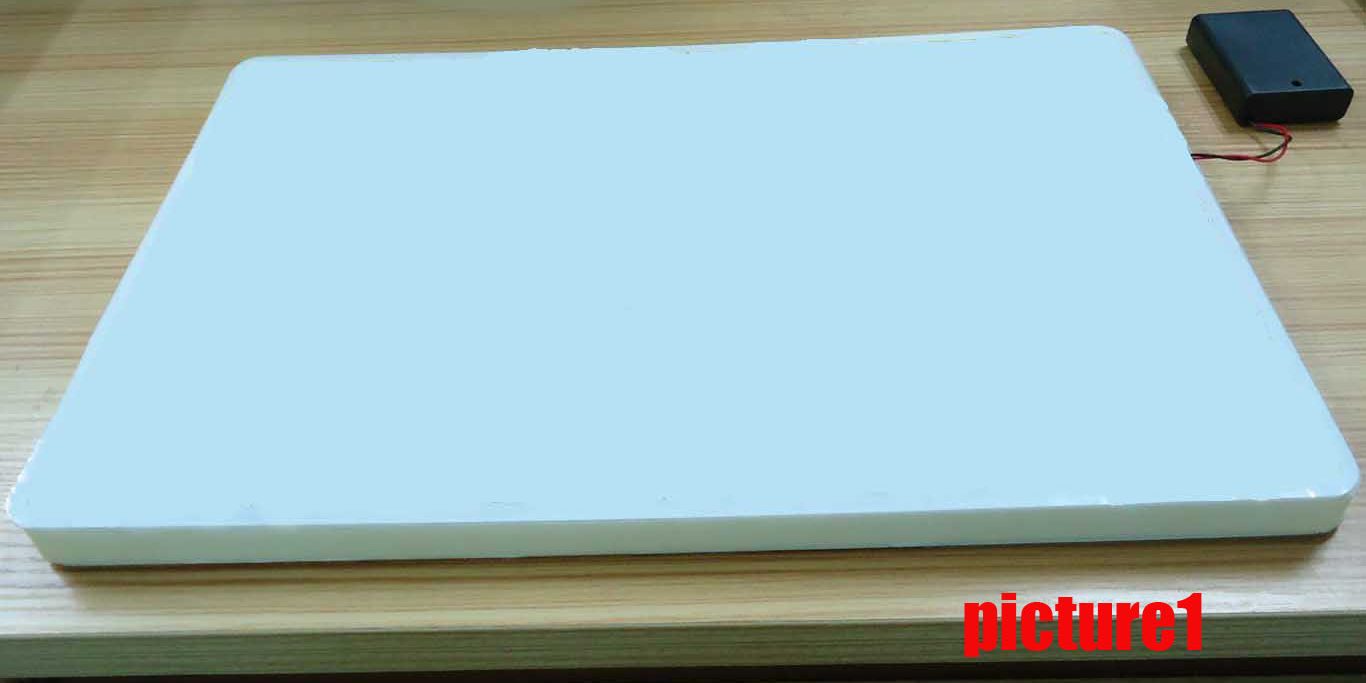

Let’s see the bottom LED backlight in picture1. It is very thick, which is 5-10 times thickness as edge LED backlight.

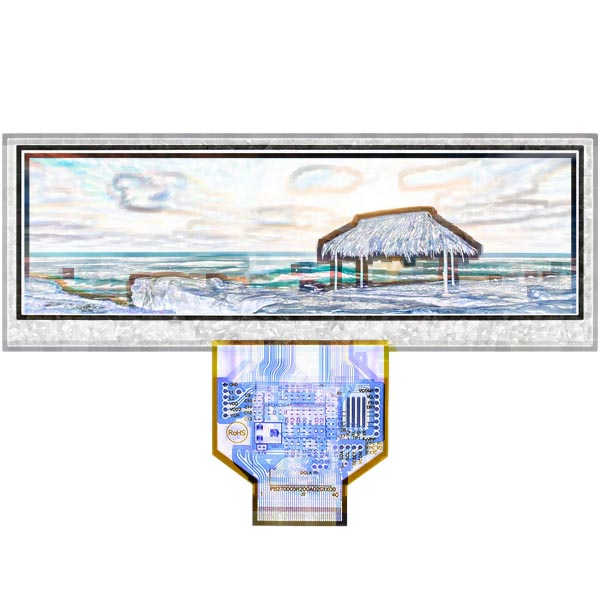

In picture3, it is a close-up of SMD LEDs.Why there are so many SMD LEDs in bottom backlight? What will happen if it has less SMD LEDs or it is thinner? Some light spots and dark areas will emerge on the surface of the light guide plate.

From the images above, we can see that the bottom light guide plate is a LED lightbox which is very thick and expensive.

2. Edge LED backlight

Let’s see two special edge LED backlights.

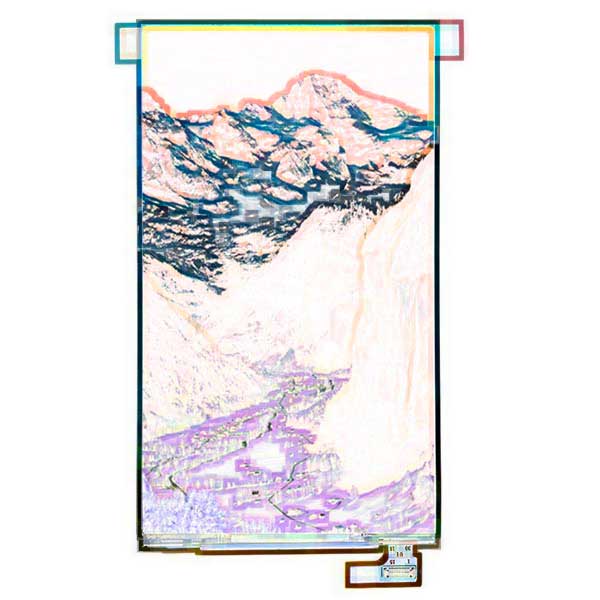

In picture4, edge LED backlight which is composed of the laser-cut light guide plate and printing light guide lattice points adopts DIP LED as the light source.

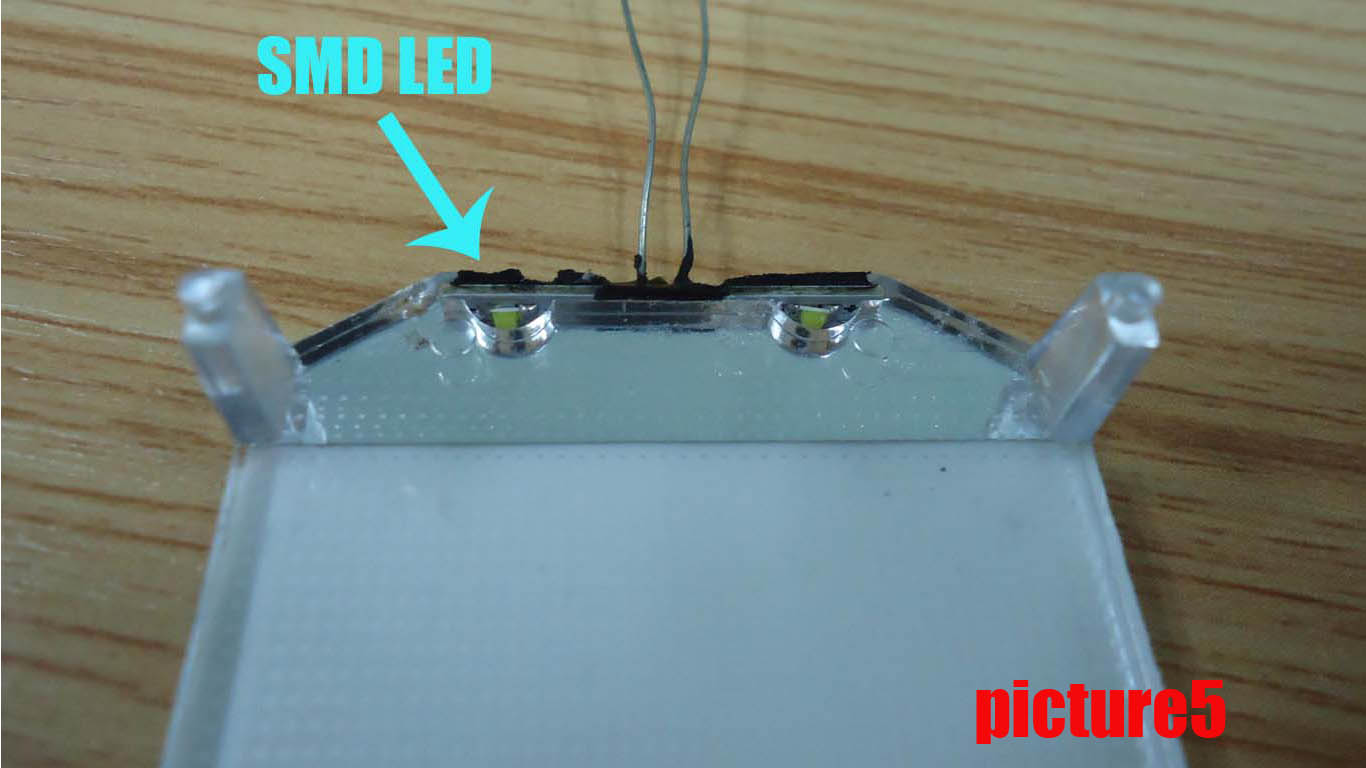

In picture5, edge LED backlight which is composed of injection molding light guide plate and non-printing light guide lattice points adopts SMD LED as the light source.

3. Bottom white LED backlight source: emphasizing on image quality performance.

Bottom white LED backlight source of liquid crystal television is better at regulating luminance than the liquid crystal television with the technology of edge white LED backlight source. Furthermore, the price of the latter is much higher, and the former has a better image performance. Taking 55 inches LED backlight liquid crystal television for example: the products with bottom white LED backlight source have more than 3000 LED lamps which are evenly distributed behind the display panel. Thus, the backlight can be evenly distributed through the entire screen and the image is much more vivid. Meanwhile, the products with edge white LED backlight source only have 400 LED lamps which are installed on the panel frame. Although this can minimize the thickness, it is very easy to cause the screen brightness with “X” shape reducing (i.e. around position is brighter than the central position) due to the reduction of the number of LED lamps.

In addition, bottom white LED backlight source liquid crystal television divides LED backlight into a number of cells. When it is displaying black, it turns off the LED lamps directly and perfectly exhibits the black. Therefore, direct type of white LED backlight source liquid crystal television can be more accurately performing the excellent color of images and the contrast effect of light and shade.

4. Edge white LED backlight source: emphasizing on super thin and energy saving.

Compared with bottom LED backlight source, edge LED backlight source requires higher level of overall design and integration ability. In addition, it increases the cost because of achieving the goal light and thin by integrating power supply of host, circuit, screen, heat dissipation and so on.

More thinner is the selling point of the edge LED backlight source TV. So far, the thinnest edge LED backlight source TV is 2.99 cm, compared with the bottom LED backlight source TV is 5.5 cm.

Is it important for the customers that the TV is getting lighter and thinner? The answer is yes. It is the obvious enhancement of the quality of products and the ultimate performance of brand and corporate R&D and manufacturing technology. The reduction of every inch of volume means the improvement of technology. In addition, edge LED backlight source TV is more energy-saving than bottom LED backlight source TV. Taking 52 inches TV boot power for example, it is only 186.5W using edge LED backlight source while it is up to 304W using bottom LED backlight source.