✨ Showcase of Micro OLED Displays

Discover the brilliance that fits in the smallest spaces.

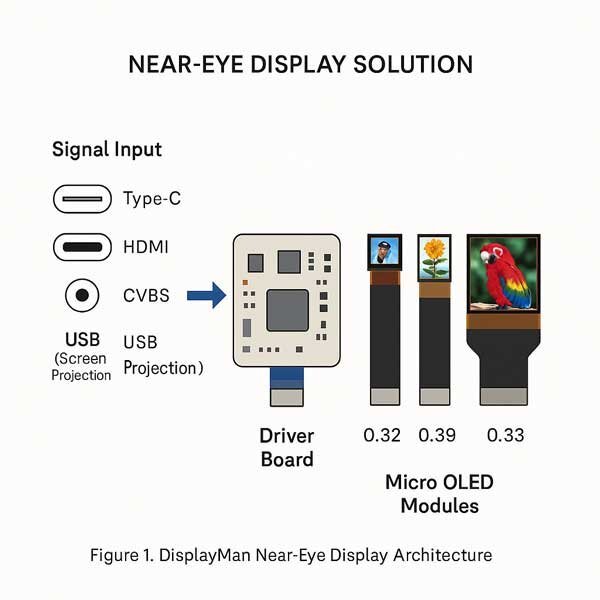

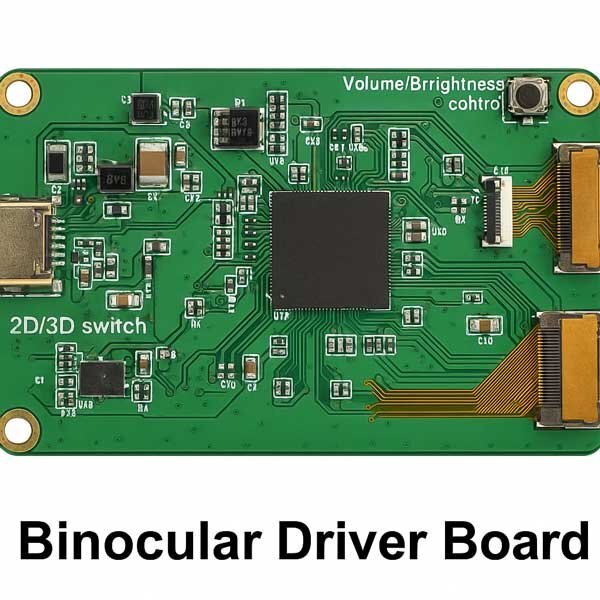

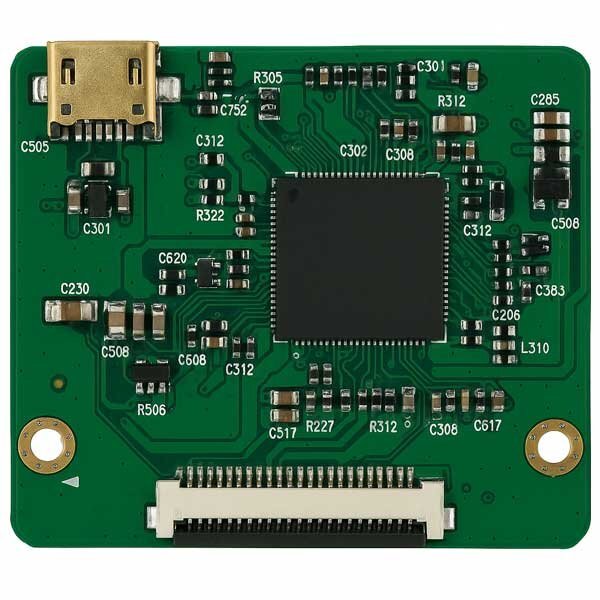

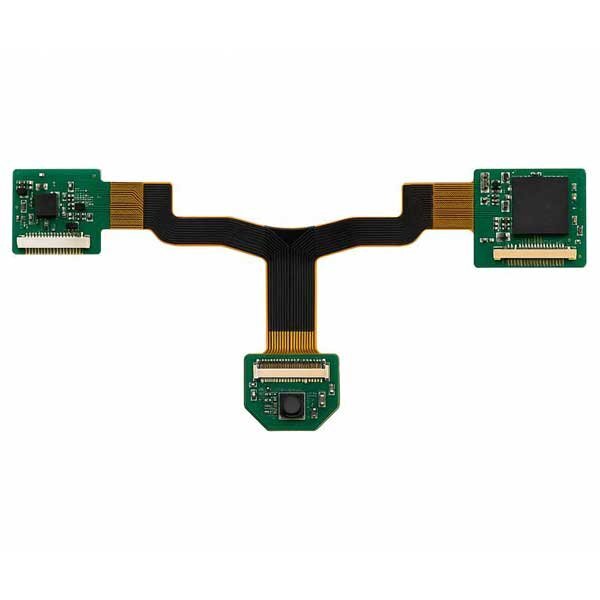

DisplayMan’s Micro OLED Displays redefine visual clarity and precision — delivering ultra-high resolution, deep contrast, and instant response in screens smaller than a postage stamp. Perfect for AR/VR optics, HUDs, scopes, and next-generation wearables, these micro displays bring cinematic quality to the most compact devices.

| Parameter | Specification |

|---|---|

| Display Size | 0.32″ |

| Resolution | 800 × 600 (SVGA) |

| Luminance (Brightness) | 2000 cd/m² |

| Interface | MIPI / RGB |

| Display Type | Micro OLED (Silicon-based) |

| Aspect Ratio | 4:3 |

| Color Depth | 24-bit (16.7M colors) |

| Response Time | < 1 ms |

| Contrast Ratio | >100,000:1 |

| Operating Temperature | -20°C ~ +70°C |

| Typical Application | Near-eye display, FPV goggles, micro optics, wearable HUD |

| Parameter | Specification |

|---|---|

| Display Size | 0.39″ |

| Resolution | 1024 × 768 (XGA) |

| Luminance (Brightness) | 600 cd/m² |

| Interface | RGB |

| Display Type | Micro OLED (Silicon-based) |

| Aspect Ratio | 4:3 |

| Color Depth | 24-bit (16.7M colors) |

| Response Time | < 1 ms |

| Contrast Ratio | >100,000:1 |

| Operating Temperature | -20°C ~ +70°C |

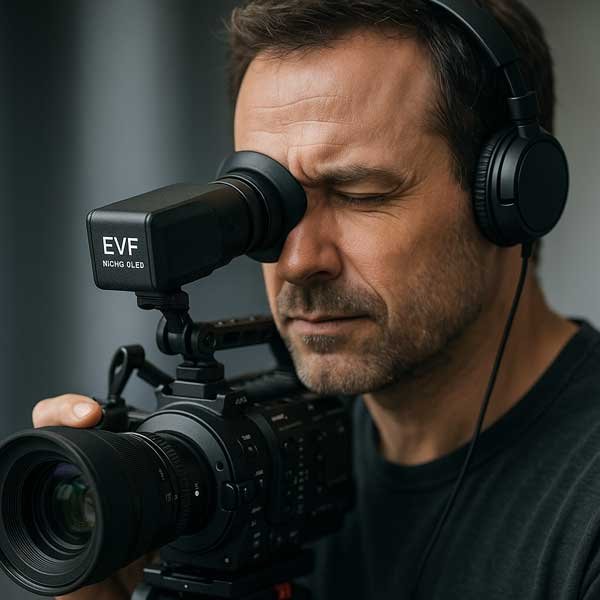

| Typical Application | Camera EVF, microscope, FPV system, optical viewfinder |

| Parameter | Specification |

|---|---|

| Display Size | 0.49″ |

| Resolution | 1920 × 1080 (Full HD) |

| Luminance (Brightness) | 1800 / 3000 / 20000 cd/m² (configurable options) |

| Interface | MIPI |

| Display Type | Micro OLED (Silicon-based) |

| Aspect Ratio | 16:9 |

| Color Depth | 24-bit (16.7M colors) |

| Response Time | < 1 ms |

| Contrast Ratio | >100,000:1 |

| Operating Temperature | -20°C ~ +70°C |

| Typical Application | AR glasses, HUD systems, EVF modules, optical R&D |

| Parameter | Specification |

|---|---|

| Display Size | 0.5″ |

| Resolution | 1600 × 1200 (UXGA) |

| Luminance (Brightness) | 1000 cd/m² |

| Interface | MIPI |

| Display Type | Micro OLED (Silicon-based) |

| Aspect Ratio | 4:3 |

| Color Depth | 24-bit (16.7M colors) |

| Response Time | < 1 ms |

| Contrast Ratio | >100,000:1 |

| Operating Temperature | -20°C ~ +70°C |

| Typical Application | AR/VR headsets, near-eye modules, medical imaging, optical R&D |

| Parameter | Specification |

|---|---|

| Display Size | 0.6″ |

| Resolution | 1920 × 1080 (Full HD) |

| Luminance (Brightness) | 6000 cd/m² |

| Interface | MIPI |

| Display Type | Micro OLED (Silicon-based) |

| Aspect Ratio | 16:9 |

| Color Depth | 24-bit (16.7M colors) |

| Response Time | < 1 ms |

| Contrast Ratio | >100,000:1 |

| Operating Temperature | -20°C ~ +70°C |

| Typical Application | AR headsets, optical research, high-brightness outdoor systems, HUD modules |

| Parameter | Specification |

|---|---|

| Display Size | 1.03″ |

| Resolution | 2560 × 2560 (2.5K) |

| Luminance (Brightness) | 1800 / 3000 / 20000 cd/m² (configurable options) |

| Interface | MIPI |

| Display Type | Micro OLED (Silicon-based) |

| Aspect Ratio | 1:1 (Square) |

| Color Depth | 24-bit (16.7M colors) |

| Response Time | < 1 ms |

| Contrast Ratio | >100,000:1 |

| Operating Temperature | -20°C ~ +70°C |

| Typical Application | VR headsets, near-eye displays, optical R&D, compact high-FOV imaging systems |

| Parameter | Specification |

|---|---|

| Display Size | 1.3″ |

| Resolution | 3552 × 3552 (3.5K) |

| Luminance (Brightness) | 4000 cd/m² |

| Interface | MIPI |

| Display Type | Micro OLED (Silicon-based) |

| Aspect Ratio | 1:1 (Square) |

| Color Depth | 24-bit (16.7M colors) |

| Response Time | < 1 ms |

| Contrast Ratio | >100,000:1 |

| Operating Temperature | -20°C ~ +70°C |

| Typical Application | AR/VR optical systems, FPV headsets, professional imaging, high-end wearable optics |