The Theory and Function of Diffusion Film

The diffusion film is the spread material that transforms the linear light source of CCFL or the point light source of LED into a uniform surface light source in the LCD module. The theory of LCD diffusion film is that making the light pass through the medium of different refractive indexes, which has been refracted, reflected and scattered, so the optical diffusion effect is made.

In general, LCD screen requires two diffusion films, the upper transparent diffusion film, and the lower white diffusion film. The main function of the lower diffusion film is that filter out the shadow of the lattice points of light guide plate and the shadow of light source and concentrate the light. The upper diffusion film not only can widen the viewing angle and strengthen the mildness of the light, but also can diffuse the light and protect the light guide plate. Diffusion film shares a small proportion of the cost of the backlight unit, compared with the light guide plate. But we should know that it is essential in the backlight unit.

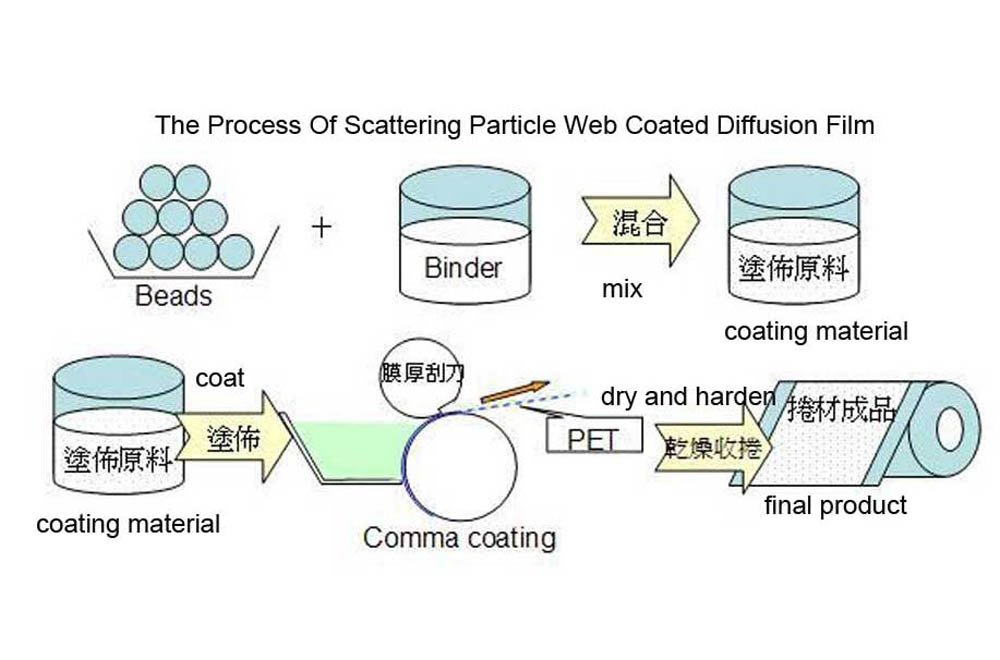

The Production Process of Diffusion Film

Diffusion film can be divided into coated diffusion film and non-coated diffusion film according to production methods. And coated diffusion film which has a higher light transmittance and a wider haze adjustment range is the first choice of the high-class backlight unit, and it can be divided into scattering particle web coated diffusion film and surface micro-structure UV coated diffusion film.

As for the structure of diffusion film, from top to bottom, diffusion layer – substrate – isolation layer. There are some special diffusion films that have a diffusion layer and an adhesive layer at the bottom. The substrate usually is a transparent optical grade PET film which has specifications of 5, 38, 50, 75, 100, 125, 150, 188 um.

The scattering particle web coated diffusion film is composed of the diffusion particles which could be inorganic particles or synthetic polymer particles and binder (acrylic resin), and the diffusion layer must be dried and hardened by high temperature. The advantage is that it is a mature and widely accepted technology and the acrylic resin is easily available. But there are several disadvantages. The coating material contains a solvent which could easily make the coating layer uneven because of their different evaporation; there is a problem in dealing solvent exhaust dealing; it is a long time and energy-consuming process for drying solvent; it a poor adhesive for scattering particles, solvent and resin; it is very difficult to control the uniform of the particles.

Surface micro-structure UV coated diffusion film is that coating a UV photosensitive material in PET film, which is embossed by the microstructure of the steel wheel (structural wheel), and the microstructure is transferred into the photosensitive material, and then it is hardened by UV.