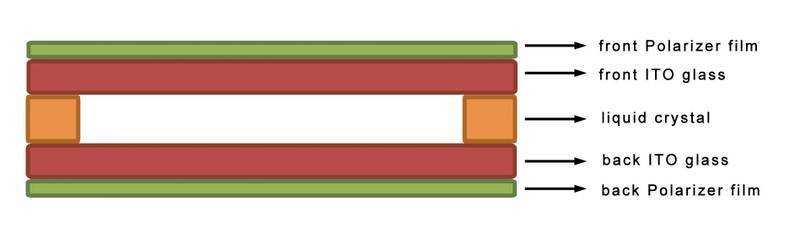

If you want to know about ITO glass and polarizer film, you must learn about the basic structure of LCD screens first.

LCD is the abbreviation for Liquid Crystal Display. Its main principle is based on stimulating the liquid crystal molecules by the current to produce points, lines and flat surfaces which compose the images we want to display with the LED backlight in the back.

From its structure, LCD is a flat display device. It looks like a sandwich that consists of a layer of liquid crystal, front and back ITO glasses, and front and back polarizer films. A liquid crystal cell is composed of front and back ITO glasses and is filled with liquid crystal and surrounded by the sealing glue (typically epoxy resin), only a liquid crystal entrance is left. There is a tiny gap between two glasses, only about a few um, which is filled by liquid crystal in vacuum conditions through the entrance. When the gap is full, the entrance will be sealed with epoxy resin, and the liquid crystal cell is done. And the front and back polarizer films are attached to the surface of the liquid crystal cell. There is an ITO conductive film between the liquid crystal and the glass. The function of the film is to bring the signal from the outside to the liquid crystal. The liquid crystal is arrayed systematically and orderly in the cell when the power is off. When the power is on, it will rearrange according to the rules we have predesigned, so it has special optical properties and electrical properties at the same time.

WHAT IS ITO GLASS?

And let us see what ITO glass is. We only add a layer of Indium Tin Oxide conductive film to the surface of normal glass, and it becomes the ITO glass. It is very simple, isn’t it?

Let me tell you something you may not know about ITO glass.

1. It is extremely transparent and well conductive.

And liquid crystal is transparent, too. We can only see some glasses and “water” under normal circumstances.

2. There are only 4 thicknesses for ITO glass: 0.4 mm, 0.55 mm, 0.7 mm and 1.1 mm.

1.1 mm ITO glass is the most commonly used and cheapest one.

| The thickness of ITO glass | The thickness of LCD panel | Price |

| 0.4 mm | 1.4 mm | higher |

| 0.55 mm | 1.7 mm | high |

| 0.7 mm | 2.0 mm | medium |

| 1.1 mm | 2.8 mm | cheap |

3. The calculation of the cost of ITO glass

ITO glass is the most important part of the cost. The size of ITO glass we use is 14*16 inch (355.6*406.4 mm)

FYI: In order to let you understand the principle better, I have simplified the calculation.

For example: we suppose the exterior size of LCD panel is 56*82 mm.

Array 1:

| 406.4 | 56 | 7.257143 | 7 |

| 355.6 | 82 | 4.336585 | 4 |

We can make 7(406.4/56) * 4(355.6/82) =28 pieces of glasses from one piece of (355.6*406.4 mm) ITO glass.

Array 2:

| 406.4 | 82 | 4.956098 | 4 |

| 355.6 | 56 | 6.35 | 6 |

We can make 4(406.4/82) * 6(355.6/56) =24 pieces of glass from one piece of (355.6*406.4 mm) ITO glass.

Thus, if we choose array 1, we can get 28 pieces of glass of 56*82 mm. But if we make the glass a little smaller, say 56*80 mm.

Array 3:

| 406.4 | 56 | 7.257143 | 7 |

| 355.6 | 80 | 4.445 | 4 |

We can make 7(406.4/56) * 4(355.6/80) =28 pieces of glass from one piece of (355.6*406.4 mm) ITO glass.

Array 4:

| 406.4 | 80 | 5.08 | 5 |

| 355.6 | 56 | 6.35 | 6 |

We can make 5(406.4/80) * 6(355.6/56) =30 pieces of glass from one piece of (355.6*406.4 mm) ITO glass.

If we choose array 4, we can get 30 pieces of glass of 56*82 mm. We only need to make the length of the glass 2.0 mm shorter and we can get 2 more pieces of glasses, which can decrease the unit price.

By the way, if the ITO glass is very small, say 8*20 mm, it will definitely increase the cost of labour. If is very large, say 150*200 mm, it will increase the cost of material loss because it will be a great loss if we accidentally break a piece of glass.

4. how to display the image we have predesigned.

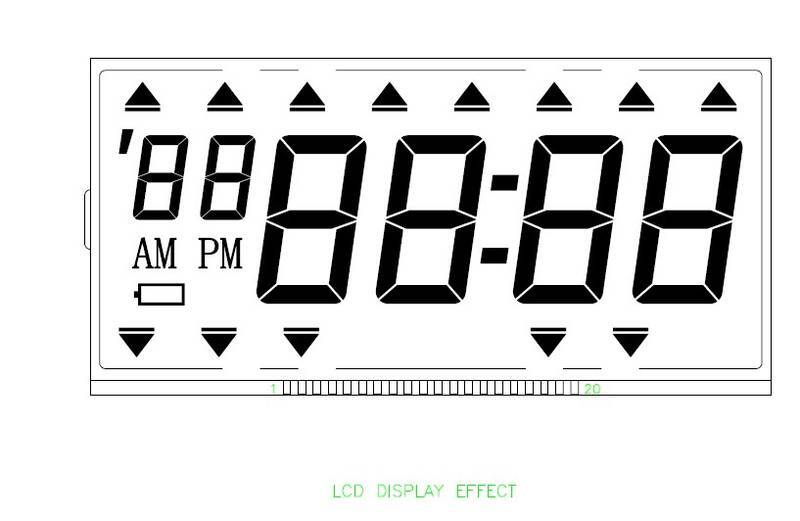

Let us take the segment LCD for example and see the picture of what an LCD display effect looks like.

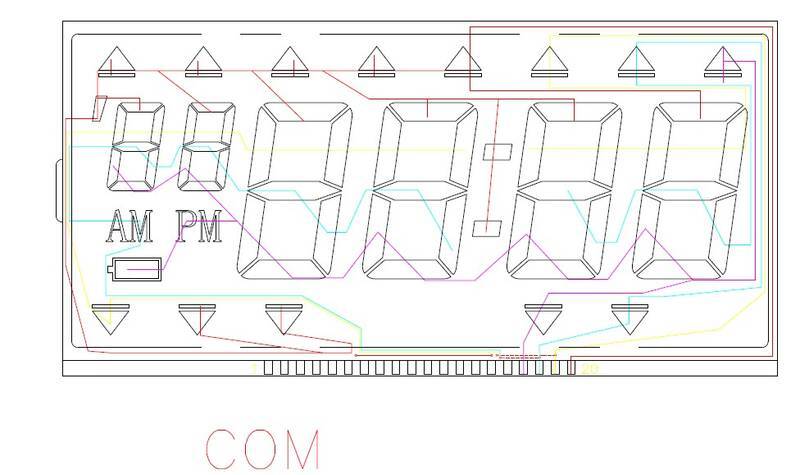

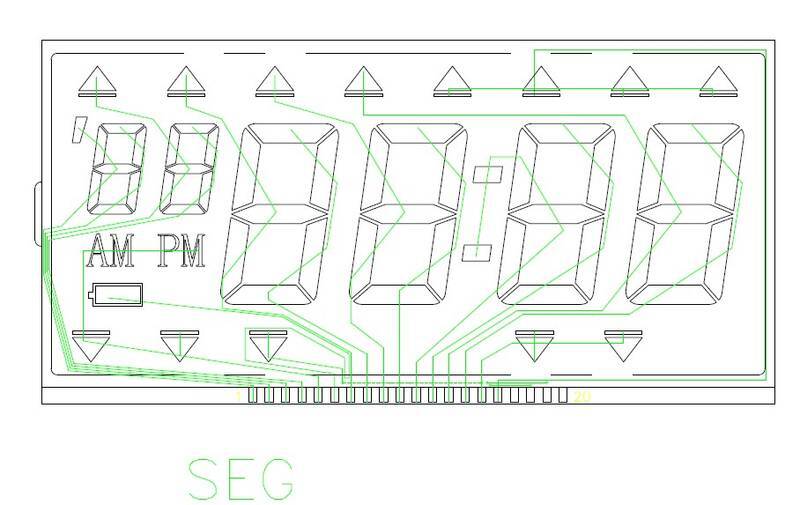

This is a 1/4 DUTY LCD panel. It has 62 segments, 62/4=16 SEG, 4 COM and total 20 PINs.

Normally, we would choose the lower glass as the PIN outlet for the SEG and the COM. The SEG and the COM are a pair. They are electrified at the same time and the segments will be lit, that is how we control the segments to display. It is as simple as that.

5. We have to wash away the useless parts of ITO film on the ITO glass, so we can get the SEG and the COM on the ITO glass.

One of my German clients told me there was an unexpected segment on 6321 LCD screen. That was because we haven’t completely cleaned the useless parts of ITO film. I have to protect my client’s privacy, so I can’t reveal the blueprint of 6321 LCD screen in this post.

6. You may wonder what the tooling fee is.

The tooling fee includes three parts: a silver halide photographic film fee, additional charges of start-up, and additional labor costs.

What is the filmng fee?

Please see the picture below:

Actually, it is a 14*16 inch (355.6*406.4 mm) film, the exact same size as ITO glass, because we need this film to make the SEG and the COM on the ITO glass. The film will be carefully preserved, which can’t be damaged under normal circumstances.

This is the tooling we charge for LCD display.

| Type | Tooling fee |

| TN | 130 USD |

| HTN | 180 USD |

| STN, FSTN, VA | 250 USD |

Why is the tooling fee different between TN, HTN and STN? You can see my post: The Comparison of TN, HTN, STN, FSTN LCD

There are two reasons:

One,

| Type | ITO glass |

| TN | normal |

| HTN | better |

| STN, FSTN, VA | best |

Two, we need additional production processes and labour costs to make the view direction. Please see my post to learn more about view direction. In other words, the view direction of LCD screen is achieved and controlled by ITO glass.

As we talk about the tooling fee, we have to refer to the quantity of the first batch. We usually send 5~20 pieces of LCD screen samples to our customers. If you have received our samples, and you want a small batch of order like 100 pieces or 500 pieces, I am sorry to inform you that we can’t make it because the quantity you demand is below the MOQ (Minimum Order Quantity) and the wastage of starting up the machine is great. Only in mass production will the machine which makes ITO glass begin to operate. Therefore, if you want a small batch of orders, I strongly suggest that it goes with the sample order.

As a matter of fact, we can’t make a penny unless we get a bulk order. The tooling fee we received can’t cover all the expenses. In other words, all the sample orders we receive are losses. And that is why some other suppliers would charge a tooling fee even it is not necessary because it does incur some costs when we make samples.

7. Silver printing is on the back of the bottom ITO glass.

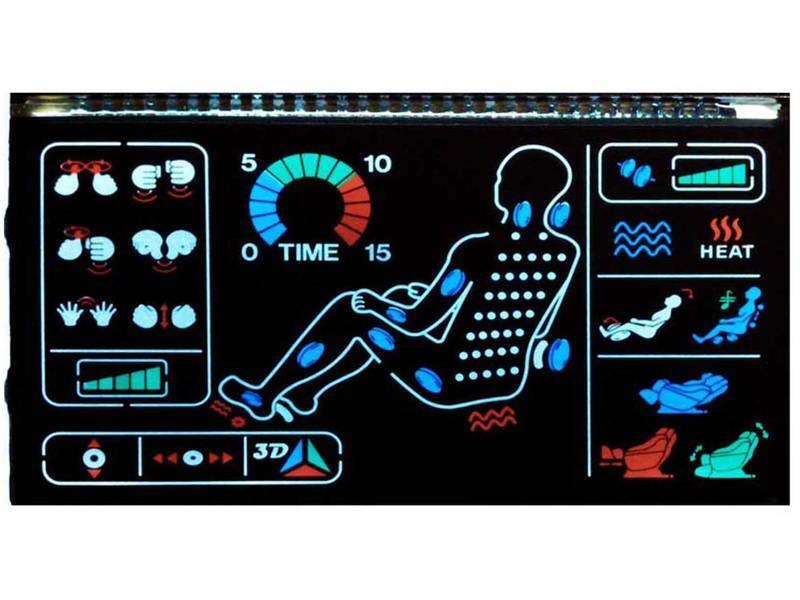

See the picture above. It has a black background and 3 colors, hasn’t it? The background is purely black, so it is a VA LCD screen. But LED backlight for this LCD screen has only one color (white), all the other three colors (blue, green and red) are silver printed on the front of ITO glass.

WHAT IS POLARIZER FILM?

Polarizer film is composed of a series of plastic films (PVA, TAC, PSA film, Release film and Protective film) which are coated with a layer of optical adhesive film which can be attached to the surface of the ITO glass.

Let me tell you something you may not know about polarizer film.

8. As we know, ITO glass and liquid crystal are transparent, the images we see on the LCD screen 100% rely on the front and back polarizer films.

If one polarizer film is missing, we can see nothing. When the power is turned off, the color we see on the surface of LCD screen is the color of the polarizer film; when the power is turned on, the light we see is the color of the LED backlight.

9. Positive and Negative displays of LCD screens depend on the front polarizer film while Transmissive, Reflective and Transflective displays of LCD screens rely on the back polarizer film.

Please see my post: Positive and Negative display and Transmissive, Reflective and Transflective display.

There are three different kinds of back polarizer film: transmissive back polarizer film, reflective back polarizer film and transflective back polarizer film. But there is only one kind of front polarizer film. If a LCD screen is a positive display, as long as we flip over the front polarizer film and attach it to the surface of the ITO glass, it’ll become a negative display LCD screen.

I want to replenish three points to LIQUID CRYSTAL.

Please see my post: An Introduction for Liquid Crystal

1. liquid crystal is no more than just a switch of light in LCD displays

All the features of LCD screens are achieved by ITO glasses, polarizer films and other optical films. But the switch function of liquid crystal is extremely important for LCD displays. Otherwise, it can’t display any image.

2. liquid crystal is divided into three grades of temperature, so LCD screens have three grades of Operating Temperature and Storage Temperature.

Please see my post: 11 Points We Must Confirm Before We Quote a Custom LCD Screen Operating Temperature and Storage Temperature section.

3. Temperature testing of LCD screen is under certain conditions and we can’t guarantee the testing results if you don’t follow the temperature testing rules.

Please see my post: How to test LCD Screen at Low and High Temperature.

Do you have any questions about ITO glass, polarizer film and liquid crystal? You are welcome to email me and leave some comments. I also would love for the comments of those who are experienced in the LCD industry to comment as well.